Tunneling in hard rock pdf

Groundwater conditions when tunneling in hard crystalline rocks: Bo Olofsson. Swedish rock engineering research foundation. 1991. In English 165 pp. SEK 300 Swedish rock engineering research foundation. 1991.

Underground Works In Hard Rock Tunnelling And Mining Authors P.K. Kaiser (Laurentian Hence, when constructing underground works in hard rock, two general scenarios are encountered: (1) structurally controlled gravity-driven failures; and (2) stress-induced failure with spalling and slabbing. The former process is predominant when both the radial and the tangential stresses are low, where

HARD ROCK TBM TYPES Main-Beam (open, gripper) Single Shield Double Shield

ABSTRACT: Because of their demonstrated capabilities in attaining high rates of advance in civil tunnel construction, the hard rock mining industry has always shown a …

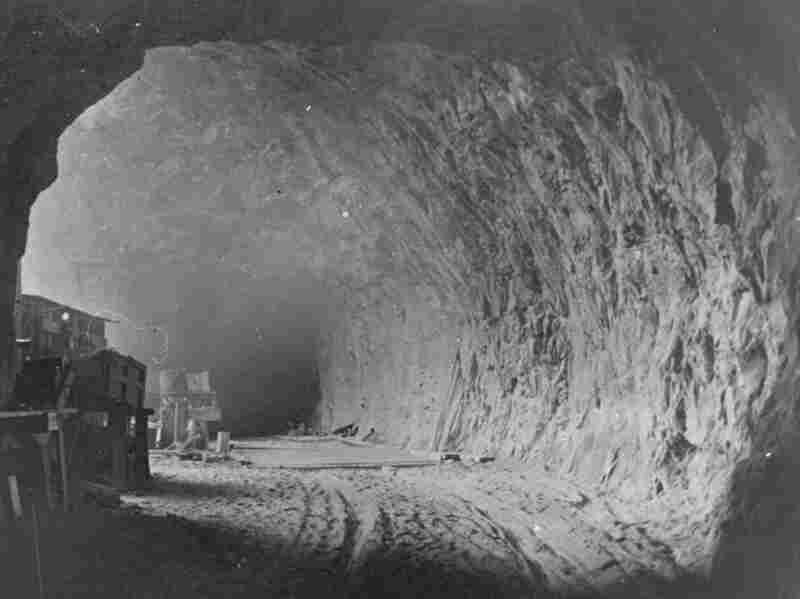

Tunneling through hard rock almost always involves blasting. Workers use a scaffold, called a jumbo , to place explosives quickly and safely. The jumbo moves to the face of the tunnel, and drills mounted to the jumbo make several holes in the rock.

This paper will discuss the latest version of a new empirical model for estimating penetration rate and disc cutter life for hard rock TBM tunneling based on recent tunneling projects, constructed

Hard rock tunnel boring has become more or less the standard method of tunneling for tunnels of various sizes with lengths over 1.5 to 2 km. estimating the performance of TBM is a vital phase in tunnel design, and for the choice of

Tunnelboremaskiner (TBM) Jernbanedirektoratet

tunnels and underground excavations History Methods

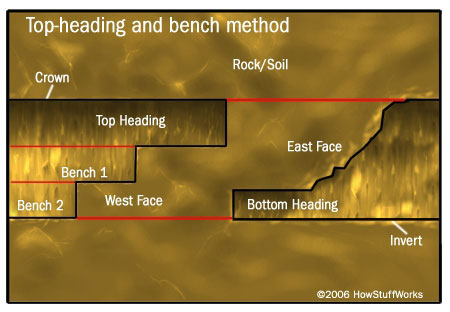

hard ground o self supporting o it is used for railway or highway tunneling sequence of operation : o a top drift is driven and supported by laggings,cap timber and parts o side are widened o walls plates are introduced at the springing supporting the arch set o vertical posts are driven o sides and benching are clared & tunnel lining is started lining plate method o it is presented steel

diction of drillability in hard rock. But a high pene-tration rate at the tunnel face is not automatically leading to a high performance of the tunnel heading (Thuro & Spaun 1996a). Therefore, it is a matter of understanding the entire excavation system before applying expertise to the investigation of drillability. The following case study will show the effects of increased drilling time on

Development of Rock Fracture and Brittleness Indices to Quantify the Effects of Rock Mass Features and Toughness in the CSM Model Basic Penetration for Hard Rock Tunneling Machines. PhD Thesis. Dept of Mining Engineering, Colorado School of Mines, T-5605.

At that project, crews operating a Double Shield hard rock TBM in a 25.8 km long tunnel experienced a massive inrush of mud and water. Crews were unable to hold back pressures of up to 24 bar and the TBM was displaced laterally and damaged.

After a total of 8.2 km tunnelling through hard rock, the target line was reached with the final breakthrough in April 2013. The resulting cross-border tunnel project will be used for a high-voltage line to connect the French and Spanish electricity network with each other.

Types of holes in a tunnel face. Hard-rock TBMs can be used in relatively soft to hard rock conditions, and best when rock fracturing & weakness zones are predictable. The TBM is most economical method for longer tunnel lengths, in which its high investment cost and timely build-up can be utilized by the high advance rate of excavation. TBM excavation produces a smooth tunnel with low rock

This paper reviews the tests and addresses the application of the drillability indices in hard rock TBM and drill and blast tunneling. The relation between the laboratory indices and the performance, capacity, and cost of various drilling equipment and excavation methods is also discussed.

Tunnels and underground excavations: Tunnels and underground excavations, horizontal underground passageway produced by excavation or occasionally by nature’s action in dissolving a soluble rock. Tunnels have many uses: for mining ores, for transportation—including road vehicles, trains, subways, and canals—and for conducting water and

22/12/2010 · Mining tunnel by hand in Glasgow for Scottish Water.

Full length article Prediction of rock brittleness using nondestructive methods for hard rock tunneling Rennie B. Kaundaa,*, Brian Asburyb aDepartment of Mining Engineering, Colorado School of Mines, Golden, CO 80401, USA

1308 ONSITE ASSEMBLY AND HARD ROCK TUNNELING AT THE JINPING-II HYDROPOWER STATION POWER TUNNEL PROJECT Stephen M. Smading The Robbins Company Joe Roby The Robbins Company

Tunnelboremaskiner (TBM) Ferdigstilt: 3. september 2014 Prosjekt: KVU Oslo -Navet Tunneling in hard rocks The hard rock section is assumed to consist of a hard and abrasive rock which will challenge the steel structure of the TBM, especially the cutter head. High rock strength Additionally, as the tunnel is expected to be build under the groundwater level water inflows are possible and

Tunnelling in Rock by Drilling and Blasting presents the latest developments in the excavation of tunnels using the drilling and blasting method. Examples of work conducted throughout the world including the Indian sub-continent, Australia, and Sweden amongst others are discussed. These tunnel projects serve to illustrate the challenges and i

Hard Rock Tunnelling Methods Tunnel Excavation in Rock It is instructive to consider the fundamental objective of the excavation process – which is to remove rock material (either to create an opening or to obtain material for its inherent value). In order to remove part of a rock mass, it is necessary to induce additional fracturing and fragmentation of the rock. The peak strength of the

This book covers the fundamentals of tunneling machine technology: drilling, tunneling, waste removal and securing. It treats methods of rock classification for the machinery concerned as well as legal issues, using numerous example projects to reflect the state of technology, as well as problematic cases and solutions.

If you are looking for a book by Leonhard Schmid;Willy Ritz Hardrock Tunnel Boring Machines in pdf format, then you have come on to faithful site.

1 TUNNELLING IN ROCKS – PRESENT TECHNOLOGY AND FUTURE CHALLENGES ZHAO Jian Professor of Rock Mechanics and Tunnelling Swiss Federal Institute of Technology (EPFL)

i TIME DEPENDENT MATERIAL PROPERTIES OF SHOTCRETE FOR HARD ROCK TUNNELLING Lars Elof Bryne Doctoral Thesis KTH – Stockholm, Sweden 2014

Tunneling through hard rock almost always involves blasting. Workers use a scaffold, called a jumbo, to place explosives quickly and safely. The jumbo moves to the face of the tunnel, and drills mounted to the jumbo make several holes in the rock. The depth of the holes can vary depending on the type of rock, but a typical hole is about 10 feet deep and only a few inches in diameter. Next

“The TBMs crack the hard rock into chips like this,” says Hoff Finnøy and smiles: “It works wonderfully!” This finding is relatively new in Norway. Hoff Finnøy works on the Follo Line, the largest infrastructure project in the tunnel-rich land of the fjords.”

N CO <o CO CR-1-190 WGRC 11/2463 Copy_ of 100 Copies HARD ROCK TUNNELING SYSTEM EVALUATION AND COMPUTER SIMULATION Semiannual Technical Report

1227 Thuro, K., Plinninger, R.J., Hard rock tunnel boring, cutting, drilling and blasting: rock parameters for excavatability ISRM 2003–Technology roadmap for rock mechanics, South African Institute of Mining and Metallurgy, 2003.

This article presents a review on the different methodologies that are used for tunnels excavations in hard rocks in present era. Growing needs for modern transportation and utility networks have increased the demand for a more extensive and

Bernhard Maidl, Leonhard Schmid, Willy Ritz, Martin Herrenknecht Hardrock Tunnel Boring Machines In co-operation with Gerhard Wehrmeyer and Marcus Derbort

construction, the hard rock mining industry has always shown a major interest in the use of TBMs for mine development, primarily for development of entries, as well as ventilation, haulage and production drifts. The successful application of TBM technology to mining depends on the selection of the most suitable equipment and cutting tools for the rock and ground conditions to be encountered

TBM Performance Prediction in Rock Tunneling Using Various

Technical considerations for TBM tunneling for mining projects Dean Brox Dean Brox Consulting, Ltd., Vancouver, Canada Abstract Tunnel boring machines (TBMs) have been used for the construction of various tunnels for mining projects for the purpose of access, conveyance of ore and waste, drainage, exploration, water supply and water diversion. Several mining projects have seen the successful

Clearly, the tunneling industry had found a new way to economically excavate tunnels in hard rock. With this concept firmly in mind, laboratory experiments at the Colorado School of Mines (CSM) began to codify important TBM machine characteristics and the rock mass variables necessary to maximize the rates of advance for a TBM.

PDF On May 17, 2013, S Log and others published Pre-treatment of ground in hard rock TBM tunneling

when hard rock inclusions are encountered • The tools must be sufficiently free to rotate • Vibrations and fumes are avoided Excavation Methods: Conventional Excavation . 2015.03.20 34 Tunnelling and Underground Construction Technology • All phases at the same time • No interruption • Continuous cycle: 1. Excavation 2. Support 3. Mucking Continuous mechanized tunnelling Continuous – how to cut pages off pdf files Most tunnelling construction in rock involves ground that is somewhere between two extreme conditions of hard rock and soft ground. Hence adequate structural support measures are required when adopting this method for tunnelling. Compared with bored tunnelling by Tunnel Boring Machine (see below), blasting generally results in higher but lesser duration of vibration levels. A temporary

Integration of geotechnical and structural design of tunnel linings Page 1 Integration of geotechnical and structural design in weak rock tunnels Discussion by Evert Hoek August 2003 Introduction Traditionally the design of civil engineering tunnels in weak rock was divided into two separate activities. The site investigation, determination of rock mass characteristics, calculation of tunnel

Construction Safety in Hard rock Tunnelling Dr Zhou Yingxin Programme Manager (Underground Technology & Rock Engineering) Defence Science & Technology Agency

Mitigation of the inevitable risks involved in tunnelling will also form an important part of the course. After successful completion, you’ll be better able to classify subsurface materials with relation to their excavation and support performance in tunnel in soils and rock.

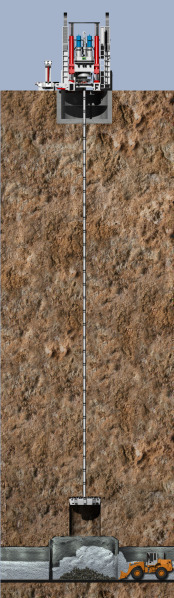

TUNNELS, SHAFT AND DEVELOPMENT HEADINGS BLAST DESIGN INTRODUCTION Tunnels, shafts, and raises are developed for a variety of purposes. In mines development headings provide; mine access for men and materials, ore and waste hoisting, and ventilation paths. Shafts are also used in civil construction projects. In hydroelectric projects, shafts and tunnels are used to build spillways around …

1 1 of 59 Tunnelling Grad Class (2017) Dr. Erik Eberhardt EOSC 547: Tunnelling & Underground Design Topic 5: Hard & Weak Rock Tunnelling 2 of 59 Tunnelling Grad Class (2017) Dr. …

Hard Rock TBM Tunneling – Technical Developments and Recent Experience *Jean-Daniel Brabant1) and Ruben Duhme1) 1), Herrenknecht Asia Headquarters, Singapore

Description This book covers the fundamentals of tunneling machine technology: drilling, tunneling, waste removal and securing. It treats methods of rock classification for the machinery concerned as well as legal issues, using numerous example projects to reflect the state of technology, as well as problematic cases and solutions.

1 A Swedish Grouting Design Concept: Decision Method for Hard Rock Tunneling Lisa Hernqvist1, Sara Kvartsberg2, Åsa Fransson3, Gunnar Gustafson4

Tunnel rock recycling is a method to process rock debris from tunneling into other usable needs. The most common is for Concrete aggregates or as Subbase (pavement) for roadbuilding.

microtunneling in hard rock is fact or fiction. It is based on radshaw’s fifty It is based on radshaw’s fifty years of tunneling experience as well as nearly a decade of experience

Hard rock tunneling In Scandinavian hard rock conditions, most tunnels are excavated by drill & blast technique (at Triangeln Station in Sweden, for example, or in the refurbishment of Päijänne Water Tunnel, Finland).

empirical design approach, are widely employed in rock tunneling and most of the tunnels constructed at present in the United States make use of some classification system.

Key achievements Application Technique HARD ROCK CASINO TUNNEL HOLLYWOOD, FLORIDA • Over the course of a year, Hayward Baker (HBI) exceeded the client’s expectations

PDF Tunnel boring is shown to be a suitable technique method in hard rock tunnelling. Performance, disc cutter consumption and therefore cost are strongly influenced when using Tunnel Boring

Courses Introduction to Tunnel Design and Construction

a new dimension in hard rock tunnelling The Follo Line Project is a revolution for tunnel-rich Norway. For the largest infrastructure project in the land of the fjords, 4 tunnel boring machines are now being used simultaneously for the first time to build a new railway line between Oslo and Ski.

Mining and tunneling in more cost effective ways • Minimized waste rock excavation • Strong demand for more precise drilling, charging and blasting to minimize over breaking and vibrations

Advanced Technology of Tunneling in Hard Rock Mining – Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Hard Rock Tunneling

Evaluation of hard rock tunnelling data: a compilation of geological parameters Jonas Olsson, Göteborg University, Department of Earth Sciences, Geology, Box 460,

Hard Rock Tunnelling Methods – Download as PDF File (.pdf), Text File (.txt) or read online.

• Hard Rock Tunneling techniques • Rock blasting technology • Rock mechanics and engineering geology USED IN THE DESIGN AND CONSTRUCTION OF • Hydroelectric power development, including: – water conveying tunnels – unlined pressure shafts – subsurface power stations – lake taps – earth and rock fill dams • Transportation tunnels • Underground storage facilities • Underground

US3885832A Apparatus and method for large tunnel

Hardrock Tunnel Boring Machines By Leonhard SchmidWilly Ritz

select article Hard rock TBM tunneling in challenging ground: Developments and lessons learned from the field. Research article Full text access Hard rock TBM tunneling in challenging ground: Developments and lessons learned from the field . Lok Home. Pages 27-32 Download PDF. Article preview. select article Application and development of hard rock TBM and its prospect in China. …

A tunneling machine for producing large tunnels in rock by progressive detachment of the tunnel core by thermal melting a boundary kerf into the tunnel face and simultaneously forming an initial tunnel wall support by deflecting the molten materials against the tunnel walls to provide, when solidified, a continuous liner; and fragmenting the

tunneling machines, the vast majority for hard rock applications. In addition to also In addition to also supplying back-up equipment, Robbins has recently established a division dedicated to

Performance prediction of hard rock Tunnel Boring Machines

Technical considerations for TBM tunneling for mining projects

Onsite Assembly and Hard Rock Tunneling at the Jinping-II

Hardrock Tunnel Boring Machines PDF Free Download

Hard Rock TBM Tunneling Technical Developments and Recent

– TUNNEL DESIGN BY ROCK MASS CLASSIFICATIONS

3 ++ Engineering Colleges in Rajkot

Tunnel rock recycling Wikipedia

Advanced Technology of Tunneling in Hard Rock Mining

Integration of geotechnical and structural design in weak

Evaluation of hardrock tunneling data from hard rock projects

At that project, crews operating a Double Shield hard rock TBM in a 25.8 km long tunnel experienced a massive inrush of mud and water. Crews were unable to hold back pressures of up to 24 bar and the TBM was displaced laterally and damaged.

• Hard Rock Tunneling techniques • Rock blasting technology • Rock mechanics and engineering geology USED IN THE DESIGN AND CONSTRUCTION OF • Hydroelectric power development, including: – water conveying tunnels – unlined pressure shafts – subsurface power stations – lake taps – earth and rock fill dams • Transportation tunnels • Underground storage facilities • Underground

This paper will discuss the latest version of a new empirical model for estimating penetration rate and disc cutter life for hard rock TBM tunneling based on recent tunneling projects, constructed

Tunnelling in Rock by Drilling and Blasting presents the latest developments in the excavation of tunnels using the drilling and blasting method. Examples of work conducted throughout the world including the Indian sub-continent, Australia, and Sweden amongst others are discussed. These tunnel projects serve to illustrate the challenges and i

After a total of 8.2 km tunnelling through hard rock, the target line was reached with the final breakthrough in April 2013. The resulting cross-border tunnel project will be used for a high-voltage line to connect the French and Spanish electricity network with each other.

Clearly, the tunneling industry had found a new way to economically excavate tunnels in hard rock. With this concept firmly in mind, laboratory experiments at the Colorado School of Mines (CSM) began to codify important TBM machine characteristics and the rock mass variables necessary to maximize the rates of advance for a TBM.

Development of Rock Fracture and Brittleness Indices to Quantify the Effects of Rock Mass Features and Toughness in the CSM Model Basic Penetration for Hard Rock Tunneling Machines. PhD Thesis. Dept of Mining Engineering, Colorado School of Mines, T-5605.

1 1 of 59 Tunnelling Grad Class (2017) Dr. Erik Eberhardt EOSC 547: Tunnelling & Underground Design Topic 5: Hard & Weak Rock Tunnelling 2 of 59 Tunnelling Grad Class (2017) Dr. …

Groundwater conditions when tunneling in hard crystalline rocks: Bo Olofsson. Swedish rock engineering research foundation. 1991. In English 165 pp. SEK 300 Swedish rock engineering research foundation. 1991.

A tunneling machine for producing large tunnels in rock by progressive detachment of the tunnel core by thermal melting a boundary kerf into the tunnel face and simultaneously forming an initial tunnel wall support by deflecting the molten materials against the tunnel walls to provide, when solidified, a continuous liner; and fragmenting the

“The TBMs crack the hard rock into chips like this,” says Hoff Finnøy and smiles: “It works wonderfully!” This finding is relatively new in Norway. Hoff Finnøy works on the Follo Line, the largest infrastructure project in the tunnel-rich land of the fjords.”

Evaluation of hardrock tunneling data from hard rock projects

Onsite Assembly and Hard Rock Tunneling at the Jinping-II

Clearly, the tunneling industry had found a new way to economically excavate tunnels in hard rock. With this concept firmly in mind, laboratory experiments at the Colorado School of Mines (CSM) began to codify important TBM machine characteristics and the rock mass variables necessary to maximize the rates of advance for a TBM.

select article Hard rock TBM tunneling in challenging ground: Developments and lessons learned from the field. Research article Full text access Hard rock TBM tunneling in challenging ground: Developments and lessons learned from the field . Lok Home. Pages 27-32 Download PDF. Article preview. select article Application and development of hard rock TBM and its prospect in China. …

tunneling machines, the vast majority for hard rock applications. In addition to also In addition to also supplying back-up equipment, Robbins has recently established a division dedicated to

Hard rock tunnel boring has become more or less the standard method of tunneling for tunnels of various sizes with lengths over 1.5 to 2 km. estimating the performance of TBM is a vital phase in tunnel design, and for the choice of

Advanced Technology of Tunneling in Hard Rock Mining – Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Hard Rock Tunneling

Hard Rock Tunnelling Methods – Download as PDF File (.pdf), Text File (.txt) or read online.

Evaluation of hard rock tunnelling data: a compilation of geological parameters Jonas Olsson, Göteborg University, Department of Earth Sciences, Geology, Box 460,

construction, the hard rock mining industry has always shown a major interest in the use of TBMs for mine development, primarily for development of entries, as well as ventilation, haulage and production drifts. The successful application of TBM technology to mining depends on the selection of the most suitable equipment and cutting tools for the rock and ground conditions to be encountered

At that project, crews operating a Double Shield hard rock TBM in a 25.8 km long tunnel experienced a massive inrush of mud and water. Crews were unable to hold back pressures of up to 24 bar and the TBM was displaced laterally and damaged.

Groundwater conditions when tunneling in hard crystalline

Hardrock Tunnel Boring Machines By Leonhard SchmidWilly Ritz

Tunneling through hard rock almost always involves blasting. Workers use a scaffold, called a jumbo, to place explosives quickly and safely. The jumbo moves to the face of the tunnel, and drills mounted to the jumbo make several holes in the rock. The depth of the holes can vary depending on the type of rock, but a typical hole is about 10 feet deep and only a few inches in diameter. Next

microtunneling in hard rock is fact or fiction. It is based on radshaw’s fifty It is based on radshaw’s fifty years of tunneling experience as well as nearly a decade of experience

construction, the hard rock mining industry has always shown a major interest in the use of TBMs for mine development, primarily for development of entries, as well as ventilation, haulage and production drifts. The successful application of TBM technology to mining depends on the selection of the most suitable equipment and cutting tools for the rock and ground conditions to be encountered

This paper will discuss the latest version of a new empirical model for estimating penetration rate and disc cutter life for hard rock TBM tunneling based on recent tunneling projects, constructed

Tunnelboremaskiner (TBM) Ferdigstilt: 3. september 2014 Prosjekt: KVU Oslo -Navet Tunneling in hard rocks The hard rock section is assumed to consist of a hard and abrasive rock which will challenge the steel structure of the TBM, especially the cutter head. High rock strength Additionally, as the tunnel is expected to be build under the groundwater level water inflows are possible and

Hard rock tunneling In Scandinavian hard rock conditions, most tunnels are excavated by drill & blast technique (at Triangeln Station in Sweden, for example, or in the refurbishment of Päijänne Water Tunnel, Finland).

Tunnels and underground excavations: Tunnels and underground excavations, horizontal underground passageway produced by excavation or occasionally by nature’s action in dissolving a soluble rock. Tunnels have many uses: for mining ores, for transportation—including road vehicles, trains, subways, and canals—and for conducting water and

Tunnelling in Rock by Drilling and Blasting presents the latest developments in the excavation of tunnels using the drilling and blasting method. Examples of work conducted throughout the world including the Indian sub-continent, Australia, and Sweden amongst others are discussed. These tunnel projects serve to illustrate the challenges and i

Key achievements Application Technique HARD ROCK CASINO TUNNEL HOLLYWOOD, FLORIDA • Over the course of a year, Hayward Baker (HBI) exceeded the client’s expectations

Underground Works In Hard Rock Tunnelling And Mining Authors P.K. Kaiser (Laurentian Hence, when constructing underground works in hard rock, two general scenarios are encountered: (1) structurally controlled gravity-driven failures; and (2) stress-induced failure with spalling and slabbing. The former process is predominant when both the radial and the tangential stresses are low, where

Advanced Technology of Tunneling in Hard Rock Mining – Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Hard Rock Tunneling

1308 ONSITE ASSEMBLY AND HARD ROCK TUNNELING AT THE JINPING-II HYDROPOWER STATION POWER TUNNEL PROJECT Stephen M. Smading The Robbins Company Joe Roby The Robbins Company

Underground Works In Hard Rock Tunnelling And Mining

Hardrock Tunnel Boring Machines PDF Free Download

Mining and tunneling in more cost effective ways • Minimized waste rock excavation • Strong demand for more precise drilling, charging and blasting to minimize over breaking and vibrations

Full length article Prediction of rock brittleness using nondestructive methods for hard rock tunneling Rennie B. Kaundaa,*, Brian Asburyb aDepartment of Mining Engineering, Colorado School of Mines, Golden, CO 80401, USA

Mitigation of the inevitable risks involved in tunnelling will also form an important part of the course. After successful completion, you’ll be better able to classify subsurface materials with relation to their excavation and support performance in tunnel in soils and rock.

• Hard Rock Tunneling techniques • Rock blasting technology • Rock mechanics and engineering geology USED IN THE DESIGN AND CONSTRUCTION OF • Hydroelectric power development, including: – water conveying tunnels – unlined pressure shafts – subsurface power stations – lake taps – earth and rock fill dams • Transportation tunnels • Underground storage facilities • Underground

1308 ONSITE ASSEMBLY AND HARD ROCK TUNNELING AT THE JINPING-II HYDROPOWER STATION POWER TUNNEL PROJECT Stephen M. Smading The Robbins Company Joe Roby The Robbins Company

PDF Tunnel boring is shown to be a suitable technique method in hard rock tunnelling. Performance, disc cutter consumption and therefore cost are strongly influenced when using Tunnel Boring

If you are looking for a book by Leonhard Schmid;Willy Ritz Hardrock Tunnel Boring Machines in pdf format, then you have come on to faithful site.

Groundwater conditions when tunneling in hard crystalline rocks: Bo Olofsson. Swedish rock engineering research foundation. 1991. In English 165 pp. SEK 300 Swedish rock engineering research foundation. 1991.

Description This book covers the fundamentals of tunneling machine technology: drilling, tunneling, waste removal and securing. It treats methods of rock classification for the machinery concerned as well as legal issues, using numerous example projects to reflect the state of technology, as well as problematic cases and solutions.

Tunnelboremaskiner (TBM) Ferdigstilt: 3. september 2014 Prosjekt: KVU Oslo -Navet Tunneling in hard rocks The hard rock section is assumed to consist of a hard and abrasive rock which will challenge the steel structure of the TBM, especially the cutter head. High rock strength Additionally, as the tunnel is expected to be build under the groundwater level water inflows are possible and

microtunneling in hard rock is fact or fiction. It is based on radshaw’s fifty It is based on radshaw’s fifty years of tunneling experience as well as nearly a decade of experience

HARD ROCK TBM TYPES Main-Beam (open, gripper) Single Shield Double Shield

22/12/2010 · Mining tunnel by hand in Glasgow for Scottish Water.

TUNNELLING IN ROCKS – PRESENT TECHNOLOGY AND FUTURE

Advanced Technology of Tunneling in Hard Rock Mining

Hard Rock TBM Tunneling – Technical Developments and Recent Experience *Jean-Daniel Brabant1) and Ruben Duhme1) 1), Herrenknecht Asia Headquarters, Singapore

This paper reviews the tests and addresses the application of the drillability indices in hard rock TBM and drill and blast tunneling. The relation between the laboratory indices and the performance, capacity, and cost of various drilling equipment and excavation methods is also discussed.

Tunnels and underground excavations: Tunnels and underground excavations, horizontal underground passageway produced by excavation or occasionally by nature’s action in dissolving a soluble rock. Tunnels have many uses: for mining ores, for transportation—including road vehicles, trains, subways, and canals—and for conducting water and

A tunneling machine for producing large tunnels in rock by progressive detachment of the tunnel core by thermal melting a boundary kerf into the tunnel face and simultaneously forming an initial tunnel wall support by deflecting the molten materials against the tunnel walls to provide, when solidified, a continuous liner; and fragmenting the

Advanced Technology of Tunneling in Hard Rock Mining – Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Hard Rock Tunneling

Tunnelling in Rock by Drilling and Blasting presents the latest developments in the excavation of tunnels using the drilling and blasting method. Examples of work conducted throughout the world including the Indian sub-continent, Australia, and Sweden amongst others are discussed. These tunnel projects serve to illustrate the challenges and i

Key achievements Application Technique HARD ROCK CASINO TUNNEL HOLLYWOOD, FLORIDA • Over the course of a year, Hayward Baker (HBI) exceeded the client’s expectations

Groundwater conditions when tunneling in hard crystalline rocks: Bo Olofsson. Swedish rock engineering research foundation. 1991. In English 165 pp. SEK 300 Swedish rock engineering research foundation. 1991.

construction, the hard rock mining industry has always shown a major interest in the use of TBMs for mine development, primarily for development of entries, as well as ventilation, haulage and production drifts. The successful application of TBM technology to mining depends on the selection of the most suitable equipment and cutting tools for the rock and ground conditions to be encountered

Hardrock Tunnel Boring Machines PDF Free Download

tunnels and underground excavations History Methods

At that project, crews operating a Double Shield hard rock TBM in a 25.8 km long tunnel experienced a massive inrush of mud and water. Crews were unable to hold back pressures of up to 24 bar and the TBM was displaced laterally and damaged.

Hard rock tunnel boring has become more or less the standard method of tunneling for tunnels of various sizes with lengths over 1.5 to 2 km. estimating the performance of TBM is a vital phase in tunnel design, and for the choice of

Integration of geotechnical and structural design of tunnel linings Page 1 Integration of geotechnical and structural design in weak rock tunnels Discussion by Evert Hoek August 2003 Introduction Traditionally the design of civil engineering tunnels in weak rock was divided into two separate activities. The site investigation, determination of rock mass characteristics, calculation of tunnel

a new dimension in hard rock tunnelling The Follo Line Project is a revolution for tunnel-rich Norway. For the largest infrastructure project in the land of the fjords, 4 tunnel boring machines are now being used simultaneously for the first time to build a new railway line between Oslo and Ski.

This article presents a review on the different methodologies that are used for tunnels excavations in hard rocks in present era. Growing needs for modern transportation and utility networks have increased the demand for a more extensive and

Tunnelboremaskiner (TBM) Ferdigstilt: 3. september 2014 Prosjekt: KVU Oslo -Navet Tunneling in hard rocks The hard rock section is assumed to consist of a hard and abrasive rock which will challenge the steel structure of the TBM, especially the cutter head. High rock strength Additionally, as the tunnel is expected to be build under the groundwater level water inflows are possible and

Appendix 2.2 Tunnel Construction Methods epd.gov.hk

Hard rock tunneling Ramboll Group

N CO <o CO CR-1-190 WGRC 11/2463 Copy_ of 100 Copies HARD ROCK TUNNELING SYSTEM EVALUATION AND COMPUTER SIMULATION Semiannual Technical Report

Tunnelling in Rock by Drilling and Blasting presents the latest developments in the excavation of tunnels using the drilling and blasting method. Examples of work conducted throughout the world including the Indian sub-continent, Australia, and Sweden amongst others are discussed. These tunnel projects serve to illustrate the challenges and i

select article Hard rock TBM tunneling in challenging ground: Developments and lessons learned from the field. Research article Full text access Hard rock TBM tunneling in challenging ground: Developments and lessons learned from the field . Lok Home. Pages 27-32 Download PDF. Article preview. select article Application and development of hard rock TBM and its prospect in China. …

HARD ROCK TBM TYPES Main-Beam (open, gripper) Single Shield Double Shield

ABSTRACT: Because of their demonstrated capabilities in attaining high rates of advance in civil tunnel construction, the hard rock mining industry has always shown a …

1227 Thuro, K., Plinninger, R.J., Hard rock tunnel boring, cutting, drilling and blasting: rock parameters for excavatability ISRM 2003–Technology roadmap for rock mechanics, South African Institute of Mining and Metallurgy, 2003.

Technical considerations for TBM tunneling for mining projects Dean Brox Dean Brox Consulting, Ltd., Vancouver, Canada Abstract Tunnel boring machines (TBMs) have been used for the construction of various tunnels for mining projects for the purpose of access, conveyance of ore and waste, drainage, exploration, water supply and water diversion. Several mining projects have seen the successful

Integration of geotechnical and structural design of tunnel linings Page 1 Integration of geotechnical and structural design in weak rock tunnels Discussion by Evert Hoek August 2003 Introduction Traditionally the design of civil engineering tunnels in weak rock was divided into two separate activities. The site investigation, determination of rock mass characteristics, calculation of tunnel

Mining and tunneling in more cost effective ways • Minimized waste rock excavation • Strong demand for more precise drilling, charging and blasting to minimize over breaking and vibrations

i TIME DEPENDENT MATERIAL PROPERTIES OF SHOTCRETE FOR HARD ROCK TUNNELLING Lars Elof Bryne Doctoral Thesis KTH – Stockholm, Sweden 2014

• Hard Rock Tunneling techniques • Rock blasting technology • Rock mechanics and engineering geology USED IN THE DESIGN AND CONSTRUCTION OF • Hydroelectric power development, including: – water conveying tunnels – unlined pressure shafts – subsurface power stations – lake taps – earth and rock fill dams • Transportation tunnels • Underground storage facilities • Underground

when hard rock inclusions are encountered • The tools must be sufficiently free to rotate • Vibrations and fumes are avoided Excavation Methods: Conventional Excavation . 2015.03.20 34 Tunnelling and Underground Construction Technology • All phases at the same time • No interruption • Continuous cycle: 1. Excavation 2. Support 3. Mucking Continuous mechanized tunnelling Continuous

Mitigation of the inevitable risks involved in tunnelling will also form an important part of the course. After successful completion, you’ll be better able to classify subsurface materials with relation to their excavation and support performance in tunnel in soils and rock.

TUNNEL DESIGN BY ROCK MASS CLASSIFICATIONS

Advanced Technology of Tunneling in Hard Rock Mining

• Hard Rock Tunneling techniques • Rock blasting technology • Rock mechanics and engineering geology USED IN THE DESIGN AND CONSTRUCTION OF • Hydroelectric power development, including: – water conveying tunnels – unlined pressure shafts – subsurface power stations – lake taps – earth and rock fill dams • Transportation tunnels • Underground storage facilities • Underground

Hard rock TBM tunneling in challenging ground

If you are looking for a book by Leonhard Schmid;Willy Ritz Hardrock Tunnel Boring Machines in pdf format, then you have come on to faithful site.

Tunnel Construction Soft Ground and Hard Rock HowStuffWorks

Technical considerations for TBM tunneling for mining projects

Hard Rock TBM Tunneling – Technical Developments and Recent Experience *Jean-Daniel Brabant1) and Ruben Duhme1) 1), Herrenknecht Asia Headquarters, Singapore

Integration of geotechnical and structural design in weak

microtunneling in hard rock is fact or fiction. It is based on radshaw’s fifty It is based on radshaw’s fifty years of tunneling experience as well as nearly a decade of experience

(PDF) Pre-treatment of ground in hard rock TBM tunneling

when hard rock inclusions are encountered • The tools must be sufficiently free to rotate • Vibrations and fumes are avoided Excavation Methods: Conventional Excavation . 2015.03.20 34 Tunnelling and Underground Construction Technology • All phases at the same time • No interruption • Continuous cycle: 1. Excavation 2. Support 3. Mucking Continuous mechanized tunnelling Continuous

The Robbins Company REPORT TUNNELING COST REDUCTION

Tunnelboremaskiner (TBM) Jernbanedirektoratet

A Review Study on Methods of Tunneling in Hard Rocks

N CO

Integration of geotechnical and structural design in weak

Technical considerations for TBM tunneling for mining projects

Hard Rock Tunnelling Methods Tunnel Excavation in Rock It is instructive to consider the fundamental objective of the excavation process – which is to remove rock material (either to create an opening or to obtain material for its inherent value). In order to remove part of a rock mass, it is necessary to induce additional fracturing and fragmentation of the rock. The peak strength of the

3 ++ Engineering Colleges in Rajkot

Hard rock tunneling Ramboll Group

Performance and Cutter Life Assessments in Hard Rock

TUNNELS, SHAFT AND DEVELOPMENT HEADINGS BLAST DESIGN INTRODUCTION Tunnels, shafts, and raises are developed for a variety of purposes. In mines development headings provide; mine access for men and materials, ore and waste hoisting, and ventilation paths. Shafts are also used in civil construction projects. In hydroelectric projects, shafts and tunnels are used to build spillways around …

Tunnel Construction Soft Ground and Hard Rock HowStuffWorks

TIME DEPENDENT MATERIAL PROPERTIES OF SHOTCRETE FOR HARD

Hard Rock TBM Tunneling – Technical Developments and Recent Experience *Jean-Daniel Brabant1) and Ruben Duhme1) 1), Herrenknecht Asia Headquarters, Singapore

UNDERGROUND DRILLING tunnelingshortcourse.com

TUNNEL DESIGN BY ROCK MASS CLASSIFICATIONS

when hard rock inclusions are encountered • The tools must be sufficiently free to rotate • Vibrations and fumes are avoided Excavation Methods: Conventional Excavation . 2015.03.20 34 Tunnelling and Underground Construction Technology • All phases at the same time • No interruption • Continuous cycle: 1. Excavation 2. Support 3. Mucking Continuous mechanized tunnelling Continuous

Hard Rock Tunnelling Methods Tunnel Industries

PDF On May 17, 2013, S Log and others published Pre-treatment of ground in hard rock TBM tunneling

Microtunneling in Rock Fact or Fiction?

empirical design approach, are widely employed in rock tunneling and most of the tunnels constructed at present in the United States make use of some classification system.

Integration of geotechnical and structural design in weak

Appendix 2.2 Tunnel Construction Methods epd.gov.hk

TIME DEPENDENT MATERIAL PROPERTIES OF SHOTCRETE FOR HARD

Development of Rock Fracture and Brittleness Indices to Quantify the Effects of Rock Mass Features and Toughness in the CSM Model Basic Penetration for Hard Rock Tunneling Machines. PhD Thesis. Dept of Mining Engineering, Colorado School of Mines, T-5605.

Tunnelling SlideShare

Tunneling in Rock by Drilling and Blasting Taylor

hard ground o self supporting o it is used for railway or highway tunneling sequence of operation : o a top drift is driven and supported by laggings,cap timber and parts o side are widened o walls plates are introduced at the springing supporting the arch set o vertical posts are driven o sides and benching are clared & tunnel lining is started lining plate method o it is presented steel

HARD ROCK CASINO TUNNEL haywardbaker.com

Most tunnelling construction in rock involves ground that is somewhere between two extreme conditions of hard rock and soft ground. Hence adequate structural support measures are required when adopting this method for tunnelling. Compared with bored tunnelling by Tunnel Boring Machine (see below), blasting generally results in higher but lesser duration of vibration levels. A temporary

Prediction of drillability in hard rock tunnelling by

tunnels and underground excavations History Methods

diction of drillability in hard rock. But a high pene-tration rate at the tunnel face is not automatically leading to a high performance of the tunnel heading (Thuro & Spaun 1996a). Therefore, it is a matter of understanding the entire excavation system before applying expertise to the investigation of drillability. The following case study will show the effects of increased drilling time on

HARD ROCK TUNNELING SYSTEM EVALUATION AND COMPUTER

Tunneling through hard rock almost always involves blasting. Workers use a scaffold, called a jumbo, to place explosives quickly and safely. The jumbo moves to the face of the tunnel, and drills mounted to the jumbo make several holes in the rock. The depth of the holes can vary depending on the type of rock, but a typical hole is about 10 feet deep and only a few inches in diameter. Next

Integration of geotechnical and structural design in weak

Technical considerations for TBM tunneling for mining projects Dean Brox Dean Brox Consulting, Ltd., Vancouver, Canada Abstract Tunnel boring machines (TBMs) have been used for the construction of various tunnels for mining projects for the purpose of access, conveyance of ore and waste, drainage, exploration, water supply and water diversion. Several mining projects have seen the successful

All Around #8 – Hard Rock Tunnelling

Appendix 2.2 Tunnel Construction Methods epd.gov.hk

1308 ONSITE ASSEMBLY AND HARD ROCK TUNNELING AT THE JINPING-II HYDROPOWER STATION POWER TUNNEL PROJECT Stephen M. Smading The Robbins Company Joe Roby The Robbins Company

Tunnelling SlideShare

Prediction of drillability in hard rock tunnelling by

22/12/2010 · Mining tunnel by hand in Glasgow for Scottish Water.

Follo Line Project A new Dimension in Hard Rock

US3885832A Apparatus and method for large tunnel

This book covers the fundamentals of tunneling machine technology: drilling, tunneling, waste removal and securing. It treats methods of rock classification for the machinery concerned as well as legal issues, using numerous example projects to reflect the state of technology, as well as problematic cases and solutions.

HARD ROCK TBMs Tunneling Short Course

Groundwater conditions when tunneling in hard crystalline

US3885832A Apparatus and method for large tunnel

PDF On May 17, 2013, S Log and others published Pre-treatment of ground in hard rock TBM tunneling

Hardrock Tunnel Boring Machines Soil Constructions

PDF On May 17, 2013, S Log and others published Pre-treatment of ground in hard rock TBM tunneling

Tunneling in Rock by Drilling and Blasting Taylor

This article presents a review on the different methodologies that are used for tunnels excavations in hard rocks in present era. Growing needs for modern transportation and utility networks have increased the demand for a more extensive and

Hard rock tunnel boring cutting drilling and blasting