What is pid controller pdf

Preface v Standard PID Control A5E00204510-02 Finding Your Way •Chapter 1 provides you with an overview of the Standard PID Control. •Chapter 2 explains the structure and the functions of the Standard PID Control.

3 Forward Tuning PID controllers can seem a mystery. Parameters that provide effective control over a process one day fail to do so the next.

What is a PID controller? A PID (Proportional Integral Derivative) controller is a common instrument used in industrial control applications. A PID controller can be used for regulation of speed, temperature, flow, pressure and other process variables.

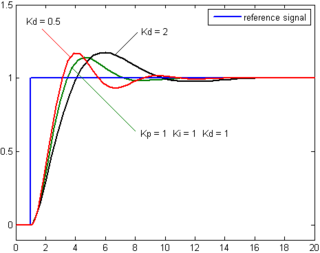

In most general pid loop, pid gains kp, kd, ki remains constant with respect to changing setpoint. This is sufficient for most of the controlling task but for making pid loop even better there is gain scheduling. In this the pid gains change with

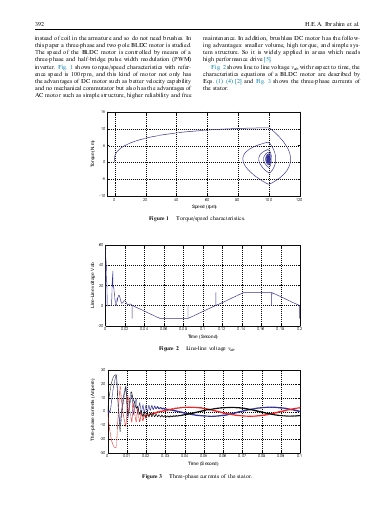

Motor Control RSS Lecture 3 Monday, 7 Feb 2011 Prof. Daniela Rus (includes some material by Prof. Seth Teller) Jones, Flynn & Seiger § 7.8.2

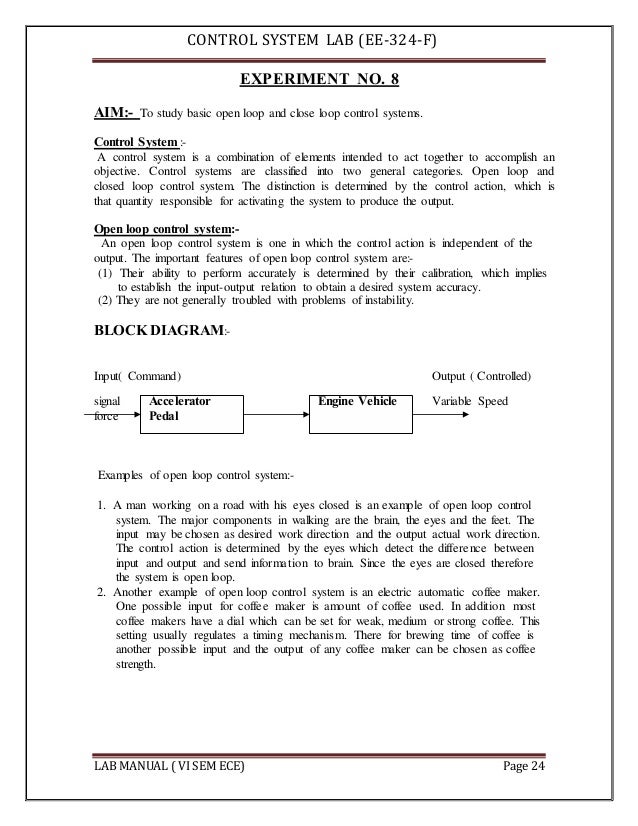

Standard PID Tuning Methods (tbco 2/17/2012) I. Cohen-Coon Method (Open-loop Test) Step 1: Perform a step test to obtain the parameters of a FOPTD (first order plus time delay) model i. Make sure the process is at an initial steady state ii. Introduce a step change in the manipulated variable iii. Wait until the process settles at a new steady state Figure 1. Step Test for Cohen-Coon Tuning

PID controllers are the most well-established class of control system. Definitions: Proportional – Proportional control gives a change in output that is proportional to the deviation of the process variable from the set point. The range over which the output is adjusted from 0 to 100% is called the proportional band. The proportional band is expressed as a percentage of the engineering range

PID controllers use a 3 basic behavior types of modes: P-proportional, I- integral and D- derivative. While Proportional and integrative modes are also used as single control modes a derivative mode is rarely used on it’s own in control systems. Such combinations such as PI and PID controller are very often in practical systems (A) Proportional (P) Controller A P controller system is a type

The PID features found in the control loops of today’s controllers have enabled us to achieve much greater accuracy in our commercial control systems at an attractive price compared to that available only a few years ago.

Even though a PID controller is designed to work with an analog output, it is possible to connect to a discrete output such as a relay. Be sure to look at the RelayOutput example below. Questions? Try the newly created Google group. The Library. Using The PID Library has two benefits in my mind There are many ways to write the PID algorithm. A lot of time was spent making the algorithm in this

PID control is so universal that PI and PID loops can be small and fast like a current-regulating loop inside a servo drive or vector controller, or a slower loop regulating the liquid level in a

13/12/2012 · In this video, I introduce the topic of PID control. This is a short introduction design to prepare you for the next few lectures where I will go through several examples of PID control. This

The PID controller looks at the setpoint and compares it with the actual value of the Process Variable (PV). Back in our house, the box of electronics that is the PID controller in our Heating and Cooling system looks at the value of the temperature sensor in the room and sees how close it is to 22°C.

P, PD, PI, PID CONTROLLERS Group Members: Sena TEMEL Semih YAĞLI Semih GÖREN. 1 Table of Contents Title Page Introduction 2 Aim of the Recitation 2 P Controller 3 P-I Controller 3 P-D Controller

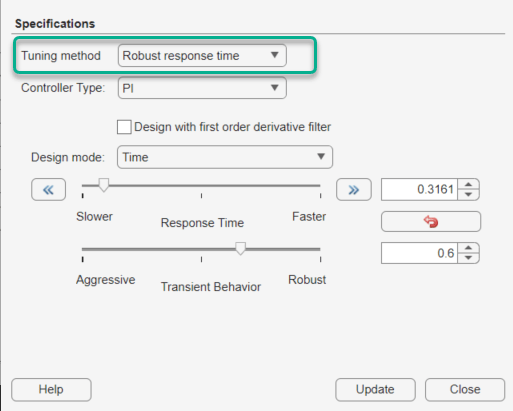

Various PID controller tuning techniques have been reported in the adaptive pid controller. It is classified into two groups, offline tuning methods as Zeigler-Nichols method and online tuning methods or adaptive PID.

PID controllers are combinations of the proportional, derivative, and integral controllers. Because of this, PID controllers have large amounts of flexibility. We will see below that there are definite limites on PID control. PID Transfer Function . The transfer function for a standard PID controller is an addition of the Proportional, the Integral, and the Differential controller transfer

Just to get it out of the way, PID stands for “Proportinal, Integral, Derivative,” and has to do with how the controller does what it does.

Proportional Integral (PI) Control A variation of Proportional Integral Derivative (PID) control is to use only the proportional and integral terms as PI control. The PI controller is the most popular variation, even more than full PID controllers.

PID WHAT IS THIS? – support.ctc-control.com

Feedforward Control BGU

PID Control 6.1 Introduction The PID controller is the most common form of feedback. It was an es-sential element of early governors and it became the standard tool when process control emerged in the 1940s. In process control today, more than 95% of the control loops are of PID type, most loops are actually PI con-trol. PID controllers are today found in all areas where control is used. The

PID, (Proportional Integral Derivative Controller) is a control loop mechanism. It’s structure and tuning is widely used in industrial control applications. It’s structure and tuning is widely used in industrial control applications.

The PID controllers have been extensively used since 1980s for the control engineering practice. The PID controller has been suggested as the second most important control decision and communication instrument of the 20 th century only behind the “Microprocessors.” 2 The cheaper

Feedforward control is always used along with feedback control because a feedback control system is required to track setpoint changes and to suppress unmeasured disturbances that are always present in any real process.

of simple PID controllers is used to control simpler processes in an industrial assembly in order to automates the certain more complex process. PID controller and its different

On-Off Controllers On-Off controllers are the simplest type of controllers featuring on-off control action designed to provide the functionality of general purpose PID controller but at a price suited to On/Off applications.

Workbook Learning System for Automation and Communications 171 149 Process Control System Control of temperature, flow and filling level

controller decreases the average power being supplied to the heater as the temperature approaches setpoint. This has the effect of slowing down the heater, so

Introduction: PID Controller Design. In this tutorial we will introduce a simple, yet versatile, feedback compensator structure: the Proportional-Integral-Derivative (PID) controller. The PID controller is widely employed because it is very understandable and because it is quite effective. One attraction of the PID controller is that all engineers understand conceptually differentiation and

between the PID tuningmethods and a design strategy for fuzzy controllers of thePID type. This paper proposes a design strategy, which makes use of known PID design tech- niques, before implementing the fuzzy controller:

– Method of letting a PID controller determine its tuning constants – A selfning algorithm that’s part of a PID controller-tu – Most stand-alone PID controllers have some form of autotune

What Is PID? Pelvic inflammatory disease, often abbreviated as PID, is a bacterial infection of the female reproductive organs – specifically the uterus, fallopian tubes, and ovaries – leading to

The PID Controller block implements a PID controller (PID, PI, PD, P only, or I only). The block is identical to the Discrete PID Controller block with the Time domain parameter set to Continuous-time .

PID control The PID controller has been in use for over a century in various forms. It has enjoyed popularity as a purely mechanical device, as a pneumatic device, and as an electronic device. The digital PID controller using a microprocessor has recently come into its own in industry. As you will see, it is a straightforward task to embed a PID controller into your code. PID stands for

22-1 Chapter 22 General Purpose PID Control 22.1 Introduction of PID Control As the general application of process control, the open loop methodology may be good enough for most situations,

78 16 control fundamentals • B is an input gain matrix for the control input u. • G is a gain matrix for unknown disturbance w; w drives the state just like the control

PID application supports a Primary and Override controller. For example, if the user wishes to control on flow rate only, a single PID (Primary) can perform the task sufficiently.

PID Controller is a most common control algorithm used in industrial automation & applications and more than 95% of the industrial controllers are of PID type. PID controllers are used for more precise and accurate control of various parameters.

Digital PID Controller Design TCHEBYSHEV REPRESENTATION AND ROOT CLUSTERING Tchebyshev representation of real polynomials ² Consider a real polynomial P(z)=a

Digital PID Controller DesignDigital PID Controller Design

Chapter 10 PID Control Based on a survey of over eleven thousand controllers in the refining, chemi-cals and pulp and paper industries, 97% of regulatory controllers utilize PID

A temperature controller is an instrument that controls temperatures, often without extensive operator involvement. In a temperature controller system, the controller accepts a temperature sensor as an input, such as an RTD or thermocouple, and compares the actual temperature with the required control temperature or setpoint.

Outline This tutorial is in PDF format with navigational control. You may press SPACE or →, or click the buttons in the lower right corner to move to the next slide.

PID Control will be useful to industry-based engineers wanting a better understanding of what is involved in the steps to a new generation of PID controller techniques. Academics wishing to have a broader perspective of PID control research and development will find useful pedagogical material and research ideas in this text.

Introduction to PID Control Introduction This introduction will show you the characteristics of the each of proportional (P), the integral (I), and the derivative (D) controls, and how to use them to obtain a desired response. In this tutorial, we will consider the following unity feedback system: Plant: A system to be controlled Controller: Provides the excitation for the plant; Designed to

Fundamentals of Servo Motion Control The fundamental concepts of servo motion control have not changed significantly in the last 50 years. The basic reasons for using servo systems in contrast to open loop systems include the need to improve transient response times, reduce the steady state errors and reduce the sensitivity to load parameters. Improving the transient response time generally

The various types of controllers are used to improve the performance of control systems. In this chapter, we will discuss the basic controllers such as the proportional, the derivative and the integral controllers. The block diagram of the unity negative feedback closed loop control system along

Discrete PID Controller for use in Robotics Project #3 . Outline Discrete Time Integrals and Derivatives Z-Transform Discrete TF of Integrals and Derivatives Discrete TF of PID Implementation of Digital PID Control Signal Limit (Saturation) Discrete Time Integrals and Derivatives . Discrete Time Integrals and Derivatives (cont.) z-Transform Discrete TF of Integrals and Derivatives Discrete TF – 2008 gmc sierra 1500 owners manual pdf The PID controller is a simple system. Well-developed architectures exist for building Well-developed architectures exist for building complex systems from the bottom up by combining PID controllers …

A fuzzy control system is a control system based on fuzzy logic—a mathematical system that analyzes analog input values in terms of logical variables that take on continuous values between 0 and 1, in contrast to classical or digital logic, which operates on …

This tutorial shows the characteristics of the proportional (P), the integral (I), and the derivative (D) controls, and how to use them to obtain a desired response. This tutorial uses LabVIEW and the LabVIEW Control Design and Simulation Module. First, let’s take a look at how the PID controller

Chapter 6 PID Controller Design PID (proportional integral derivative) control is one of the earlier control strategies [59]. Its early implementation was in pneumatic devices, followed by vacuum and solid state analog electronics, before arriving at today’s digital implementation of microprocessors. It has a simple control structure which was understood by plant operators and which they

The PID Control Algorithm How it works, how to tune it, and how to use it 2nd Edition John A. Shaw Process Control Solutions December 1, 2003 . Introduction ii John A. Shaw is a process control engineer and president of Process Control Solutions. An engineering graduate of N. C. State University, he previously worked for Duke Power Company in Charlotte, N. C. and for Taylor Instrument …

Need for control system. Controllers. Different controllers Proportional(P) controller. Advantages and drawbacks of P Control Proportional integral(PI) controller. Advantages and drawbacks of PI controller PD controller. Advantages and drawbacks Proportional Integral Derivative(PID) controller. Advantages and drawbacks Demonstration. References z; 2. z FLO Gds) Gp(s) Plant / Process Process

Process Control Laboratory. 7. PID Controllers. 7.1.2 The series form of a PID controller. In the pre-digital era it was convenient to implement an analog PID controller as a

PDF This paper presents the modeling of a four rotor vertical take-off and landing (VTOL) unmanned air vehicle known as the quad rotor aircraft. The paper presents a new model design method for

Common Industrial Applications of PID Control. PID Control May Struggle With Noise But There are Numerous Applications Where It’s the Perfect Fit. A previous post about the Derivative Term focused on its weaknesses. As noted, the primary challenge associated with the use of Derivative and PID Control is the volatility of the controller’s response when in the presence of noise. Noise is a

EE392m – Winter 2003 Control Engineering 4-1 Lecture 4 – PID Control • 90% (or more) of control loops in industry are PID • Simple control design model → simple controller

Process Control and Instrumentation online training, tutorials and information – Learn all the basics, theory and practical application of industrial systems and devices. Instrumentation, Process Control and Industrial Automation Training.

Chapter 19 Programming the PID Algorithm Introduction The PID algorithm is used to control an analog process having a single control point and a single feedback signal. The PID algorithm controls the output to the control point so that a setpoint is achieved. The setpoint may be entered as a static variable or as a dynamic variable that is calculated from a mathematical operation. For many

Process Control Most industrial processes require that certain variables such as temperature, flow, level or pressure, remain at or near some reference value (setpoint). Closed-loop control is used to achieve this. The process controller looks at a signal representing the process value, compares it to the desired setpoint and acts on the process to minimize the difference (error). The method

In its simplest terms, PID is a type of control used to stabilize servo drives. PID can be implemented either in analog or digital and be used with hydraulic or electrical servo drives. The process of stabilizing servo drives has been described as an equalization process, or some times referred to as compensation of a servo system. There are two ways to assess servo drives. The first is how

PID Control made easy. Introduction to the key terms associated with PID Temperature Control ON / OFF Control. On / Off control is the simplest means of control but gives rise to fluctuations in the process variable (Fig 1). A degree of hysteresis or deadband must be set in On / Off control if the operation of the switching device is to be reduced and relay chatter is to be avoided (Fig 2). On

Install a controller (in this case a PID controller), and connect it to the electronic temperature measurement and the automated control valve. A PID controller has a Set Point (SP) that the operator can set to the desired temperature.

In PID Controller 1, PID is no longer connected with rates, so changing P will not affect rotation speed, e.g. increasing P gains does not make rates sluggish. It gives you much better yaw response. What I heard the most from those who use PID Controller=1 is, “the control response seems more direct, feels more locked in”, and “no need for TPA anymore”. This is recommended PID

of the PID controllers of Figure 10.4 from a well-designed and well-tuned IMC cascade control system, just as we did for single-loop control systems in Chapter 6. Figure 10.5 shows an IMC cascade block diagram that accomplishes the same

Measurement Products PID control theory made easy

Introduction Potential Induced Degradation (PID) is an undesirable property of some solar modules. The factors that enable PID (voltage, heat and humidity) exist on all

PID might be slightly different when it comes to implementation, thus how P,I and D affects the system (there are now 6 PID controllers). Not sure how good you are with coding, if you can check out how PID controller is implemented in Baseflight/cleanflight that should help your multirotor tuning.

The EZ-ZONE PM is a panel mount controller that can be offered as a PID controller, limit controller or the functions can be combined as an integrated controller.

Arduino Playground PIDLibrary

Introduction to PID Control Sharif University of Technology

PID controller 0 1 and 2 in CleanFlight Explained Part

Understanding PID Temperature Control Eurotherm

Tuning Of Fuzzy PID Controllers Petra Christian University

SIMATIC Standard PID Control Siemens

Basics of PID Control (Proportional+Integral+Derivative

applications of ultrasound for class 9 – ADAPTIVE PID CONTROLLER PDF Maissana PDF

What is PID Control? – osPID

CHA PTER 10

Chapter 22 General Purpose PID Control SEA Praha

Temperature Controllers What Is It How It Works & Types

Understanding Potential Induced Degradation Advanced Energy

Digital PID Controller Design TCHEBYSHEV REPRESENTATION AND ROOT CLUSTERING Tchebyshev representation of real polynomials ² Consider a real polynomial P(z)=a

EE392m – Winter 2003 Control Engineering 4-1 Lecture 4 – PID Control • 90% (or more) of control loops in industry are PID • Simple control design model → simple controller

controller decreases the average power being supplied to the heater as the temperature approaches setpoint. This has the effect of slowing down the heater, so

In PID Controller 1, PID is no longer connected with rates, so changing P will not affect rotation speed, e.g. increasing P gains does not make rates sluggish. It gives you much better yaw response. What I heard the most from those who use PID Controller=1 is, “the control response seems more direct, feels more locked in”, and “no need for TPA anymore”. This is recommended PID

PID Control A brief introduction – YouTube

Feedforward Control BGU

The PID Control Algorithm How it works, how to tune it, and how to use it 2nd Edition John A. Shaw Process Control Solutions December 1, 2003 . Introduction ii John A. Shaw is a process control engineer and president of Process Control Solutions. An engineering graduate of N. C. State University, he previously worked for Duke Power Company in Charlotte, N. C. and for Taylor Instrument …

The various types of controllers are used to improve the performance of control systems. In this chapter, we will discuss the basic controllers such as the proportional, the derivative and the integral controllers. The block diagram of the unity negative feedback closed loop control system along

The PID controllers have been extensively used since 1980s for the control engineering practice. The PID controller has been suggested as the second most important control decision and communication instrument of the 20 th century only behind the “Microprocessors.” 2 The cheaper

13/12/2012 · In this video, I introduce the topic of PID control. This is a short introduction design to prepare you for the next few lectures where I will go through several examples of PID control. This

controller decreases the average power being supplied to the heater as the temperature approaches setpoint. This has the effect of slowing down the heater, so

What is a PID controller? A PID (Proportional Integral Derivative) controller is a common instrument used in industrial control applications. A PID controller can be used for regulation of speed, temperature, flow, pressure and other process variables.

Process Control Most industrial processes require that certain variables such as temperature, flow, level or pressure, remain at or near some reference value (setpoint). Closed-loop control is used to achieve this. The process controller looks at a signal representing the process value, compares it to the desired setpoint and acts on the process to minimize the difference (error). The method

PID control is so universal that PI and PID loops can be small and fast like a current-regulating loop inside a servo drive or vector controller, or a slower loop regulating the liquid level in a

PID Control will be useful to industry-based engineers wanting a better understanding of what is involved in the steps to a new generation of PID controller techniques. Academics wishing to have a broader perspective of PID control research and development will find useful pedagogical material and research ideas in this text.

Chapter 6 PID Controller Design PID (proportional integral derivative) control is one of the earlier control strategies [59]. Its early implementation was in pneumatic devices, followed by vacuum and solid state analog electronics, before arriving at today’s digital implementation of microprocessors. It has a simple control structure which was understood by plant operators and which they

16 CONTROL FUNDAMENTALS MIT OpenCourseWare

What is PID Control? – osPID

Introduction: PID Controller Design. In this tutorial we will introduce a simple, yet versatile, feedback compensator structure: the Proportional-Integral-Derivative (PID) controller. The PID controller is widely employed because it is very understandable and because it is quite effective. One attraction of the PID controller is that all engineers understand conceptually differentiation and

Need for control system. Controllers. Different controllers Proportional(P) controller. Advantages and drawbacks of P Control Proportional integral(PI) controller. Advantages and drawbacks of PI controller PD controller. Advantages and drawbacks Proportional Integral Derivative(PID) controller. Advantages and drawbacks Demonstration. References z; 2. z FLO Gds) Gp(s) Plant / Process Process

The EZ-ZONE PM is a panel mount controller that can be offered as a PID controller, limit controller or the functions can be combined as an integrated controller.

What is a PID controller? A PID (Proportional Integral Derivative) controller is a common instrument used in industrial control applications. A PID controller can be used for regulation of speed, temperature, flow, pressure and other process variables.

The various types of controllers are used to improve the performance of control systems. In this chapter, we will discuss the basic controllers such as the proportional, the derivative and the integral controllers. The block diagram of the unity negative feedback closed loop control system along

Install a controller (in this case a PID controller), and connect it to the electronic temperature measurement and the automated control valve. A PID controller has a Set Point (SP) that the operator can set to the desired temperature.

On-Off Controllers On-Off controllers are the simplest type of controllers featuring on-off control action designed to provide the functionality of general purpose PID controller but at a price suited to On/Off applications.

Introduction to PID Control Introduction This introduction will show you the characteristics of the each of proportional (P), the integral (I), and the derivative (D) controls, and how to use them to obtain a desired response. In this tutorial, we will consider the following unity feedback system: Plant: A system to be controlled Controller: Provides the excitation for the plant; Designed to

PID Control made easy. Introduction to the key terms associated with PID Temperature Control ON / OFF Control. On / Off control is the simplest means of control but gives rise to fluctuations in the process variable (Fig 1). A degree of hysteresis or deadband must be set in On / Off control if the operation of the switching device is to be reduced and relay chatter is to be avoided (Fig 2). On

PID Control National Instruments

Process Control Systems Industrial Automation Training

The EZ-ZONE PM is a panel mount controller that can be offered as a PID controller, limit controller or the functions can be combined as an integrated controller.

Various PID controller tuning techniques have been reported in the adaptive pid controller. It is classified into two groups, offline tuning methods as Zeigler-Nichols method and online tuning methods or adaptive PID.

PID controllers use a 3 basic behavior types of modes: P-proportional, I- integral and D- derivative. While Proportional and integrative modes are also used as single control modes a derivative mode is rarely used on it’s own in control systems. Such combinations such as PI and PID controller are very often in practical systems (A) Proportional (P) Controller A P controller system is a type

Standard PID Tuning Methods (tbco 2/17/2012) I. Cohen-Coon Method (Open-loop Test) Step 1: Perform a step test to obtain the parameters of a FOPTD (first order plus time delay) model i. Make sure the process is at an initial steady state ii. Introduce a step change in the manipulated variable iii. Wait until the process settles at a new steady state Figure 1. Step Test for Cohen-Coon Tuning

Outline This tutorial is in PDF format with navigational control. You may press SPACE or →, or click the buttons in the lower right corner to move to the next slide.

On-Off Controllers On-Off controllers are the simplest type of controllers featuring on-off control action designed to provide the functionality of general purpose PID controller but at a price suited to On/Off applications.

Process Control and Instrumentation online training, tutorials and information – Learn all the basics, theory and practical application of industrial systems and devices. Instrumentation, Process Control and Industrial Automation Training.

The PID Control Algorithm How it works, how to tune it, and how to use it 2nd Edition John A. Shaw Process Control Solutions December 1, 2003 . Introduction ii John A. Shaw is a process control engineer and president of Process Control Solutions. An engineering graduate of N. C. State University, he previously worked for Duke Power Company in Charlotte, N. C. and for Taylor Instrument …

Fundamentals of Servo Motion Control The fundamental concepts of servo motion control have not changed significantly in the last 50 years. The basic reasons for using servo systems in contrast to open loop systems include the need to improve transient response times, reduce the steady state errors and reduce the sensitivity to load parameters. Improving the transient response time generally

Introduction Potential Induced Degradation (PID) is an undesirable property of some solar modules. The factors that enable PID (voltage, heat and humidity) exist on all

ADAPTIVE PID CONTROLLER PDF Maissana PDF

What is PID Control? – osPID

78 16 control fundamentals • B is an input gain matrix for the control input u. • G is a gain matrix for unknown disturbance w; w drives the state just like the control

PID, (Proportional Integral Derivative Controller) is a control loop mechanism. It’s structure and tuning is widely used in industrial control applications. It’s structure and tuning is widely used in industrial control applications.

Introduction to PID Control Introduction This introduction will show you the characteristics of the each of proportional (P), the integral (I), and the derivative (D) controls, and how to use them to obtain a desired response. In this tutorial, we will consider the following unity feedback system: Plant: A system to be controlled Controller: Provides the excitation for the plant; Designed to

– Method of letting a PID controller determine its tuning constants – A selfning algorithm that’s part of a PID controller-tu – Most stand-alone PID controllers have some form of autotune

Process Control and Instrumentation online training, tutorials and information – Learn all the basics, theory and practical application of industrial systems and devices. Instrumentation, Process Control and Industrial Automation Training.

Discrete PID Controller Koç Hastanesi

Control Systems Controllers – Tutorials Point

Digital PID Controller Design TCHEBYSHEV REPRESENTATION AND ROOT CLUSTERING Tchebyshev representation of real polynomials ² Consider a real polynomial P(z)=a

Outline This tutorial is in PDF format with navigational control. You may press SPACE or →, or click the buttons in the lower right corner to move to the next slide.

In its simplest terms, PID is a type of control used to stabilize servo drives. PID can be implemented either in analog or digital and be used with hydraulic or electrical servo drives. The process of stabilizing servo drives has been described as an equalization process, or some times referred to as compensation of a servo system. There are two ways to assess servo drives. The first is how

PID Control will be useful to industry-based engineers wanting a better understanding of what is involved in the steps to a new generation of PID controller techniques. Academics wishing to have a broader perspective of PID control research and development will find useful pedagogical material and research ideas in this text.

Workbook Learning System for Automation and Communications 171 149 Process Control System Control of temperature, flow and filling level

between the PID tuningmethods and a design strategy for fuzzy controllers of thePID type. This paper proposes a design strategy, which makes use of known PID design tech- niques, before implementing the fuzzy controller:

Understanding and Design of an Arduino-based PID Controller

16 CONTROL FUNDAMENTALS MIT OpenCourseWare

PID Control will be useful to industry-based engineers wanting a better understanding of what is involved in the steps to a new generation of PID controller techniques. Academics wishing to have a broader perspective of PID control research and development will find useful pedagogical material and research ideas in this text.

PID Control made easy. Introduction to the key terms associated with PID Temperature Control ON / OFF Control. On / Off control is the simplest means of control but gives rise to fluctuations in the process variable (Fig 1). A degree of hysteresis or deadband must be set in On / Off control if the operation of the switching device is to be reduced and relay chatter is to be avoided (Fig 2). On

Install a controller (in this case a PID controller), and connect it to the electronic temperature measurement and the automated control valve. A PID controller has a Set Point (SP) that the operator can set to the desired temperature.

The PID Control Algorithm How it works, how to tune it, and how to use it 2nd Edition John A. Shaw Process Control Solutions December 1, 2003 . Introduction ii John A. Shaw is a process control engineer and president of Process Control Solutions. An engineering graduate of N. C. State University, he previously worked for Duke Power Company in Charlotte, N. C. and for Taylor Instrument …

PID controllers are combinations of the proportional, derivative, and integral controllers. Because of this, PID controllers have large amounts of flexibility. We will see below that there are definite limites on PID control. PID Transfer Function . The transfer function for a standard PID controller is an addition of the Proportional, the Integral, and the Differential controller transfer

Digital PID Controller Design TCHEBYSHEV REPRESENTATION AND ROOT CLUSTERING Tchebyshev representation of real polynomials ² Consider a real polynomial P(z)=a

The various types of controllers are used to improve the performance of control systems. In this chapter, we will discuss the basic controllers such as the proportional, the derivative and the integral controllers. The block diagram of the unity negative feedback closed loop control system along

Various PID controller tuning techniques have been reported in the adaptive pid controller. It is classified into two groups, offline tuning methods as Zeigler-Nichols method and online tuning methods or adaptive PID.

Chapter 19 Programming the PID Algorithm

Common Industrial Applications of PID Control Control

22-1 Chapter 22 General Purpose PID Control 22.1 Introduction of PID Control As the general application of process control, the open loop methodology may be good enough for most situations,

PID without a PhD University of Colorado Colorado Springs

Overview of Process Control and Controller Modes Weschler

controller decreases the average power being supplied to the heater as the temperature approaches setpoint. This has the effect of slowing down the heater, so

What is adaptive PID controller? Quora

Digital PID Controller Design TCHEBYSHEV REPRESENTATION AND ROOT CLUSTERING Tchebyshev representation of real polynomials ² Consider a real polynomial P(z)=a

Comparative study of P PI and PID controller for speed

PID Control SpringerLink

Introduction PID Controller Design University of Michigan

Introduction Potential Induced Degradation (PID) is an undesirable property of some solar modules. The factors that enable PID (voltage, heat and humidity) exist on all

Chapter 22 General Purpose PID Control SEA Praha

Feedforward control is always used along with feedback control because a feedback control system is required to track setpoint changes and to suppress unmeasured disturbances that are always present in any real process.

PID Controllers for Temperature Regulation and Temperature

Measurement Products PID control theory made easy

In most general pid loop, pid gains kp, kd, ki remains constant with respect to changing setpoint. This is sufficient for most of the controlling task but for making pid loop even better there is gain scheduling. In this the pid gains change with

Understanding PID Temperature Control Eurotherm

What is adaptive PID controller? Quora

3 Forward Tuning PID controllers can seem a mystery. Parameters that provide effective control over a process one day fail to do so the next.

Comparative study of P PI and PID controller for speed

Measurement Products PID control theory made easy

controller decreases the average power being supplied to the heater as the temperature approaches setpoint. This has the effect of slowing down the heater, so

Arduino Playground PIDLibrary

Introduction to PID Control Sharif University of Technology

The PID controller looks at the setpoint and compares it with the actual value of the Process Variable (PV). Back in our house, the box of electronics that is the PID controller in our Heating and Cooling system looks at the value of the temperature sensor in the room and sees how close it is to 22°C.

Control Systems/Controllers and Compensators Wikibooks

PDF This paper presents the modeling of a four rotor vertical take-off and landing (VTOL) unmanned air vehicle known as the quad rotor aircraft. The paper presents a new model design method for

What Is PID? Definition Causes Symptoms & Treatment

What is a PID controller? A PID (Proportional Integral Derivative) controller is a common instrument used in industrial control applications. A PID controller can be used for regulation of speed, temperature, flow, pressure and other process variables.

Discrete PID Controller Koç Hastanesi

This tutorial shows the characteristics of the proportional (P), the integral (I), and the derivative (D) controls, and how to use them to obtain a desired response. This tutorial uses LabVIEW and the LabVIEW Control Design and Simulation Module. First, let’s take a look at how the PID controller

Common Industrial Applications of PID Control Control

Control Systems/Controllers and Compensators Wikibooks

Discrete PID Controller Koç Hastanesi

controller decreases the average power being supplied to the heater as the temperature approaches setpoint. This has the effect of slowing down the heater, so

Continuous-time or discrete-time PID controller Simulink

What is a PID controller? A PID (Proportional Integral Derivative) controller is a common instrument used in industrial control applications. A PID controller can be used for regulation of speed, temperature, flow, pressure and other process variables.

PID without a PhD University of Colorado Colorado Springs

Continuous-time or discrete-time PID controller Simulink

csTUNER PID Tuning Guide Yokogawa Electric

Introduction to PID Control Introduction This introduction will show you the characteristics of the each of proportional (P), the integral (I), and the derivative (D) controls, and how to use them to obtain a desired response. In this tutorial, we will consider the following unity feedback system: Plant: A system to be controlled Controller: Provides the excitation for the plant; Designed to

Feedforward Control BGU

Understanding PID Temperature Control Eurotherm

Feedforward control is always used along with feedback control because a feedback control system is required to track setpoint changes and to suppress unmeasured disturbances that are always present in any real process.

PID for Dummies Control Solutions – csimn.com

Proportional Integral (PI) Control APMonitor

PDF This paper presents the modeling of a four rotor vertical take-off and landing (VTOL) unmanned air vehicle known as the quad rotor aircraft. The paper presents a new model design method for

Chapter 19 Programming the PID Algorithm

PID Controllers for Temperature Regulation and Temperature

16 CONTROL FUNDAMENTALS MIT OpenCourseWare

Introduction to PID Control Introduction This introduction will show you the characteristics of the each of proportional (P), the integral (I), and the derivative (D) controls, and how to use them to obtain a desired response. In this tutorial, we will consider the following unity feedback system: Plant: A system to be controlled Controller: Provides the excitation for the plant; Designed to

SIMATIC Standard PID Control Siemens

Standard PID Tuning Methods (tbco 2/17/2012) I. Cohen-Coon Method (Open-loop Test) Step 1: Perform a step test to obtain the parameters of a FOPTD (first order plus time delay) model i. Make sure the process is at an initial steady state ii. Introduce a step change in the manipulated variable iii. Wait until the process settles at a new steady state Figure 1. Step Test for Cohen-Coon Tuning

How Does a PID Controller Work? Structure & Tuning Methods

Basics of PID Control (Proportional+Integral+Derivative

Understanding Potential Induced Degradation Advanced Energy

PID control is so universal that PI and PID loops can be small and fast like a current-regulating loop inside a servo drive or vector controller, or a slower loop regulating the liquid level in a

Process Laboratory Control 7. PID Controllers Startsida

EE392m – Winter 2003 Control Engineering 4-1 Lecture 4 – PID Control • 90% (or more) of control loops in industry are PID • Simple control design model → simple controller

CHA PTER 10

The PID Controller block implements a PID controller (PID, PI, PD, P only, or I only). The block is identical to the Discrete PID Controller block with the Time domain parameter set to Continuous-time .

LECTURES ON PID CONTROLLERS UT Arlington – UTA

Basics of PID Control (Proportional+Integral+Derivative

The EZ-ZONE PM is a panel mount controller that can be offered as a PID controller, limit controller or the functions can be combined as an integrated controller.

PID Controllers Explained Control Notes

Fuzzy control system Wikipedia

What is PID Control? – osPID

EE392m – Winter 2003 Control Engineering 4-1 Lecture 4 – PID Control • 90% (or more) of control loops in industry are PID • Simple control design model → simple controller

What is adaptive PID controller? Quora

– Method of letting a PID controller determine its tuning constants – A selfning algorithm that’s part of a PID controller-tu – Most stand-alone PID controllers have some form of autotune

Watlow EZ-ZONE PM Panel Mount Controller PID Controller

Continuous-time or discrete-time PID controller Simulink

The PID features found in the control loops of today’s controllers have enabled us to achieve much greater accuracy in our commercial control systems at an attractive price compared to that available only a few years ago.

Control system theory IIT Kanpur

Understanding Potential Induced Degradation Advanced Energy

16 CONTROL FUNDAMENTALS MIT OpenCourseWare

PID controllers use a 3 basic behavior types of modes: P-proportional, I- integral and D- derivative. While Proportional and integrative modes are also used as single control modes a derivative mode is rarely used on it’s own in control systems. Such combinations such as PI and PID controller are very often in practical systems (A) Proportional (P) Controller A P controller system is a type

Introduction to PID Control Sharif University of Technology

Control system theory IIT Kanpur

This tutorial shows the characteristics of the proportional (P), the integral (I), and the derivative (D) controls, and how to use them to obtain a desired response. This tutorial uses LabVIEW and the LabVIEW Control Design and Simulation Module. First, let’s take a look at how the PID controller

Control system theory IIT Kanpur

Process Control Most industrial processes require that certain variables such as temperature, flow, level or pressure, remain at or near some reference value (setpoint). Closed-loop control is used to achieve this. The process controller looks at a signal representing the process value, compares it to the desired setpoint and acts on the process to minimize the difference (error). The method

Fuzzy control system Wikipedia

Introduction to PID Control Sharif University of Technology

PID Controllers for Temperature Regulation and Temperature